We have had our obstacles with this project and really had to utilize our own resources to complete an end result of a 3D model. It is currently (hopefully) being printed after our last hiccup this week. The TA needed the STL file for the model to print and the group sent it to them on Tuesday. Our presentation is tomorrow, so hopefully it will be printed.

To recap the group experimented with 123-D Catch and Mesh Mixer to create a model, but was unsuccessful. We had to shift gears and create a new strategy after finding that the class' resources were not for us. Susan was able to obtain and print the blueprints for the building while Albert was able to use his Creo expertise to create a model quickly. DeDe, Alex, and Susan became proficient in 123-D Catch, although not used. Alex worked on pre-made models with Mesh mixer extensively.

The entire group was able to understand what it was like to be in an engineering group where there is not too much structure. The group had to work together to create their own personal goals to complete the task of a 3-D model. They worked together and learned how unpredictable engineering can be. Multitasking and quickly changing tasks was definitely a skill that all group members picked up. Will update on how the actual model looks and our success with the poster contest.

Group 085-09: Paul Peck 3-D Printed Model

Wednesday, June 3, 2015

Week 8 & 9

These weeks have been going a little slower due to the project being completed week 8.

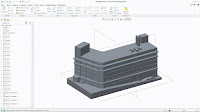

Albert was incredible and able to create an entirely new model in Creo. he was able to use the blue prints and dimensions to create a detailed model that accurately depicts the building. Pictures will be at the end. The model is at a 250:1 scale and just barely fits the printer requirements. Unfortunately, the Google Earth model and the 123D catch model were not used. The group had to think outside of the box and are very pleased at the end product.

Susan, Dede, and Alex worked on completing the final report and the poster for the poster contest. Our group was selected out of the section for having an unique project and asked to compete against the other sections. We created a poster that is between the (information wise) the final report and the PowerPoint. The group will be judged week 10 on June 4th, 2015.

Albert was incredible and able to create an entirely new model in Creo. he was able to use the blue prints and dimensions to create a detailed model that accurately depicts the building. Pictures will be at the end. The model is at a 250:1 scale and just barely fits the printer requirements. Unfortunately, the Google Earth model and the 123D catch model were not used. The group had to think outside of the box and are very pleased at the end product.

Susan, Dede, and Alex worked on completing the final report and the poster for the poster contest. Our group was selected out of the section for having an unique project and asked to compete against the other sections. We created a poster that is between the (information wise) the final report and the PowerPoint. The group will be judged week 10 on June 4th, 2015.

|

| Final Model (back) |

|

| Final Model (side) |

|

| Final Model (front) |

Week 7:

This week the group had a large leap in progress and felt much more confident!

Albert was able to have a basic foundation model that he created using google earth. The fellows were impressed and thought it was a good start. The details from the building needed to be in the final 3-D model created, however, they felt it was a very creative solution. We felt that a model was possible in the next two weeks and Albert was excited to use Creo to accomplish this. Alex, Susan, and DeDe were a little concerned he would not be able to create a model in enough time, however we have faith in him.

DeDe was able to stitch together an impressive amount of photos using 123D catch, however they will not be used in the end model. Our pictures were not good enough quality and the size of our building played a large role in that. The largest side of the Paul Peck Research and Development building was over 200 photos. This would mean at least three different stitched together pieces of side.

Susan and Alex worked on the blog and figured out how to submit a 3D print request form. It is coming down to the wire and are a little concerned because the bulk of the project will need to be done outside of class. They also worked on the final report draft. Susan collected sources and Alex formatted.

Albert was able to have a basic foundation model that he created using google earth. The fellows were impressed and thought it was a good start. The details from the building needed to be in the final 3-D model created, however, they felt it was a very creative solution. We felt that a model was possible in the next two weeks and Albert was excited to use Creo to accomplish this. Alex, Susan, and DeDe were a little concerned he would not be able to create a model in enough time, however we have faith in him.

DeDe was able to stitch together an impressive amount of photos using 123D catch, however they will not be used in the end model. Our pictures were not good enough quality and the size of our building played a large role in that. The largest side of the Paul Peck Research and Development building was over 200 photos. This would mean at least three different stitched together pieces of side.

Susan and Alex worked on the blog and figured out how to submit a 3D print request form. It is coming down to the wire and are a little concerned because the bulk of the project will need to be done outside of class. They also worked on the final report draft. Susan collected sources and Alex formatted.

|

| 123D Catch Front Image |

|

| 123D Catch Back Image |

|

| Google Earth Model |

|

| Google Earth Model |

Monday, May 18, 2015

Week 6:

This week the group did not make that much progress in terms of working on the actual project, but reorganizing the project and figuring the next steps.

De spent a while during class figuring out how to use 123d catch and getting the pictures in order. It was difficult to use the pictures we used to create a 3-d model because all of the photos looked the same. We took about 200 pictures for the long side of the Building and the program was unable to recognize them as being individual pictures, so the program made De manually select common points. We also discovered how long it takes to actually stitch the photos together.

Susan waited for the blog to be checked as well as fixed it so it comprised all of the required parts. This included a bio for the professor and a FAQ tab. She also discussed an updated target calendar for the remaining of the weeks. It was surprising how close to the actual caleneder the group was.

Alex spent a while trying to work with meshmixer and figure out how we were going to make our model water tight. The software has some premade pieces and shapes that he was using to play around.

De spent a while during class figuring out how to use 123d catch and getting the pictures in order. It was difficult to use the pictures we used to create a 3-d model because all of the photos looked the same. We took about 200 pictures for the long side of the Building and the program was unable to recognize them as being individual pictures, so the program made De manually select common points. We also discovered how long it takes to actually stitch the photos together.

Susan waited for the blog to be checked as well as fixed it so it comprised all of the required parts. This included a bio for the professor and a FAQ tab. She also discussed an updated target calendar for the remaining of the weeks. It was surprising how close to the actual caleneder the group was.

Alex spent a while trying to work with meshmixer and figure out how we were going to make our model water tight. The software has some premade pieces and shapes that he was using to play around.

Wednesday, May 6, 2015

Week 5:

Thursday:

We were having a rough time at the beginning of the week because we had no pictures and really no measurements, however, it quickly turned around. On Monday Albert tried to fly the drone to get pictures, however, a gust of wind broke it. On Thursday the group was unsure about what to do because we might have had to pay for it, but we were able to hot glue it back together.

Now on to the exciting part! We not only got all of the pictures we needed, but was able to get the CAD model as well as the information needed for measurements. We are well on our way in this process and the future for the Paul Peck 3-D model is looking up. We thankfully had excellent sunlight last Thursday and was able to use the Iphone 6 plus to take fairly good photos. We were all shocked.

Albert is attempting to stitch together the photos and have at least one side done by class week six, but an update will follow. He has had some issues reinstalling AutoCAD.

|

| One of the photos we took to stitch together |

|

| Another! |

|

| Alex and Susan had some fun with the caution tape |

Monday, April 27, 2015

Week 4:

This week was not very productive and the group was unable to use

the surveying equipment very effectively. This week the we met Monday from 3-5 pm and Thursday during class,however, there will be only one post. This is due to there not being too much to say.

the surveying equipment very effectively. This week the we met Monday from 3-5 pm and Thursday during class,however, there will be only one post. This is due to there not being too much to say.

Monday:

De, Alex, and Susan tried to use the surveying equipment to get the measurements of the side of Paul Peck not along a street. This seemed like the best side to start on, however, police cars kept moving in and out of the lot. We had to move the equipment around quite a bit and kept trying to recalibrate. We were about the find the angle between us and the wall and the straight length to find the length of the side (of Paul Peck). This was all we accomplished as it was impossible to use the equipment to find the height. We were not able to go far enough back. It took forever because each time we moved we had to adjust the equipment. Please note we were also all sweating. FUN FACT: A man passing us told us that the surveying stick we were using was called a "Philadelphia Rod" and we looked it up. It is!

|

| De finding the right corner of building |

|

| Susan with the "Philadelphia Rod" |

Thursday:

During class we all went back to the Paul Peck building and had little success. First one of the calibration wheels did not work so the group was unable to really use the surveying equipment accurately. It took a lot of maneuvering. There was no possible to get the height of the building due to cars. De and Susan tried to stand on Calhoun's lawn, but it was unachievable. Albert and Alex literally by hand took the remaining measurements of the base. We will have to get the height another way. We emailed facilities and they said they will get us the plans as soon as possible as well as some are online. There did not seem to be any that showed height. Next week we are focusing on flying and taking pictures. Fingers crossed this all works out!

Monday, April 20, 2015

Week 3:

Thursday:

Today the group had class and spent the majority of the class planning out the next few weeks and adjusting accordingly. We had to have our blog and design proposal checked and that took up a considerable amount of time. We agreed that meeting outside of class is a necessity and that we were going to meet Monday from 3-5.

Not much else was done, however, everyone took a field trip to the building and discussed how to survey and drive the drone. There is no good way to take drone pictures of the back as seen in the pictures below. This is due to the elevated group and giant fence in the back. Furthermore, everyone was concerned that the majority of the building is on street sides. It was really important to look at the building in real life as the google earth pictures of the Paul Peck Research building are not great.

|

| The gorgeous front of our building |

|

| The building with the group! |

|

| The fence and back of Paul Peck |

|

| The back of Paul Peck building |

|

| Where our done will not go! |

Subscribe to:

Comments (Atom)